Applications

All Applications

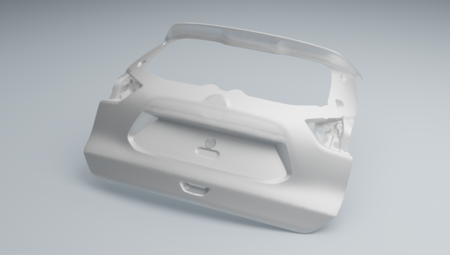

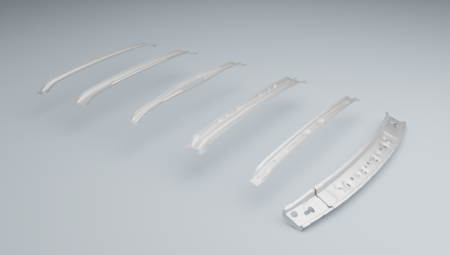

Tailgate

- Tailgate made of Tailor Welded Blanks for 14 % weight reduction compared to monoplates

- Reduced joining operations

- Reduction in overall costs

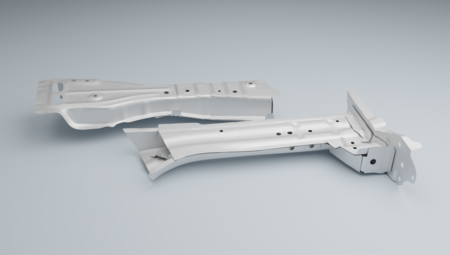

Longitudinal member

- Tailor-welded blanks made of dual-phase steel for 15% higher strength compared with monoplates

- Functional enhancement through specifically adapted materials and thicknesses

Your partner:

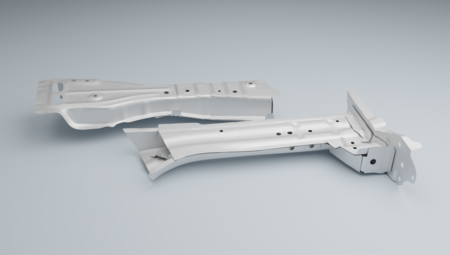

Longitudinal member (IHU-Part)

- High stiffness due to closed profiles

- Optimum work-hardening potential, due to homogeneous forming

Your partner:

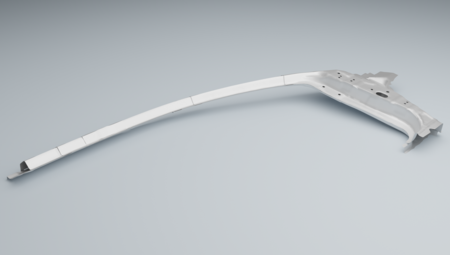

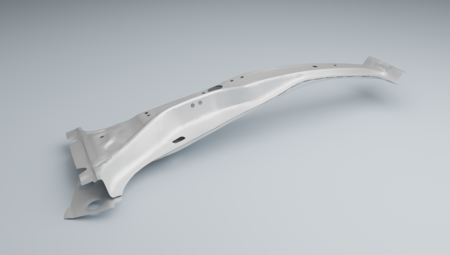

A-pillar/ roof frame (IHU-Part)

- Extreme forming degrees with excellent operational strength

- Simultaneous weight savings due to one-piece tailored tube as starting material

Your partner:

Roof cross member

- High lightweight performance & stiffness

- Excellent operational strength and precision

Your partner:

Engine bracket

- Extensive range of coil pre-processing to slit strips, strip sheets and blanks

Your partner:

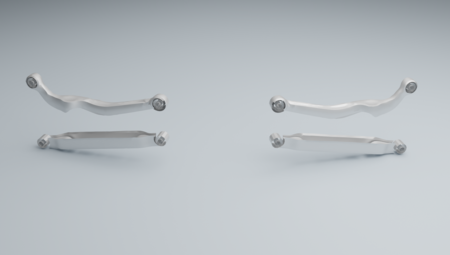

Suspension control arm

- Innovative complex-phase steels with high fatigue strength for dynamically stressed components

- Lightweight potential due to sheet thickness reduction and component-specific design

Your partner:

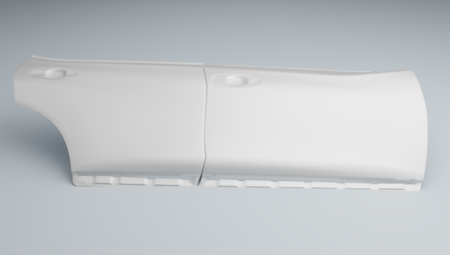

Door

- Wide range of processing options

- With our partners we cover all wishes in the vertical range of manufacture up to the complete assembly or component

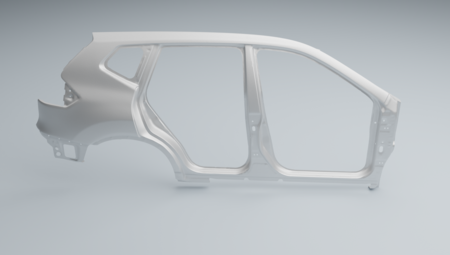

Side Wall

- Dual-phase steels with high strength combined with good formability.

- Our StronSal® hot-dip coating enables weight savings by reducing the coating thickness while retaining excellent corrosion protection properties

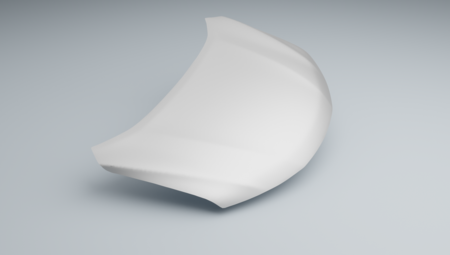

Hood

- Dual-phase steels with high strength combined with good formability.

- Our StronSal® hot-dip coating enables weight savings by reducing the coating thickness while retaining excellent corrosion protection properties

B-Pillar

- Tailor-welded blanks made of dual-phase steel for 15% higher strength compared with monoplates

- Functional enhancement through specifically adapted materials and thicknesses

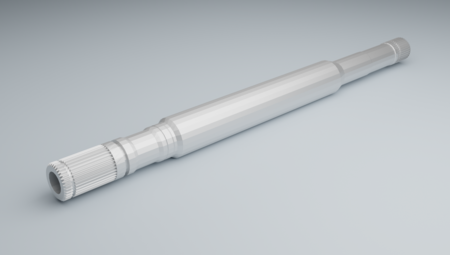

Side shaft

- Excellent formability

- Low edge decarburization

- Excellent eccentricity and surface quality

Your partner:

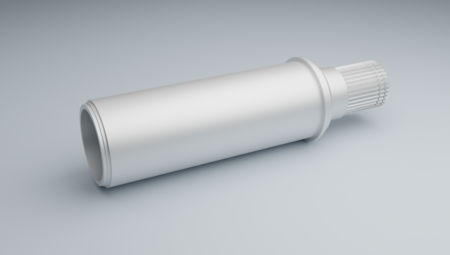

Rotor shaft

- Close dimensional, form and positional tolerances

- High formability and component service life

- Optimized surface quality and low hardening distortion

Your partner: