Products &

Services

All Products

Hot rolled products

- Hot-rolled dual-phase steels for high formability combined with high strength.

- Air-hardening RobuSal steels, specially developed for automotive applications

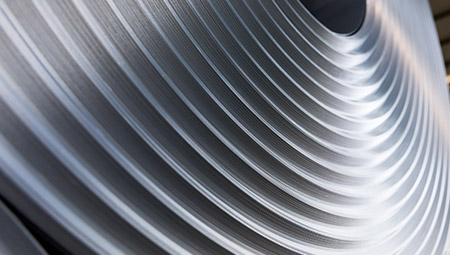

Cold rolled sheet

- "Wide range of high-strength steels with very good processing properties for automotive construction

- Lightweight solutions thanks to low plate thickness while ensuring the required crash properties

Surface treated sheets

- Pretex® process for improved processing properties during forming and painting.

- StronSal®: Zinc-magnesium coating with outstanding corrosion protection properties.

- FolaSal®: coil-coated sheets

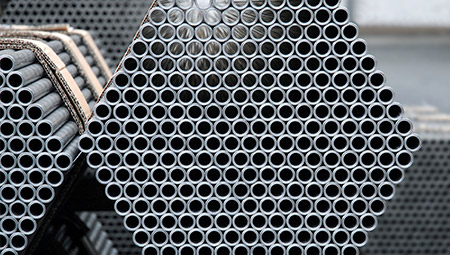

Precision steel tubes

- Extensive portfolio of seamless or welded tubes, as well as hot-finished tubes and profiles.

- Diverse solutions for powertrain, chassis, body, transmission, steering, fuel supply or occupant protection

Stainless steel pipes

- World's leading seamless stainless steel and nickel-based tube products

- Hot and cold finished austenitic tubes

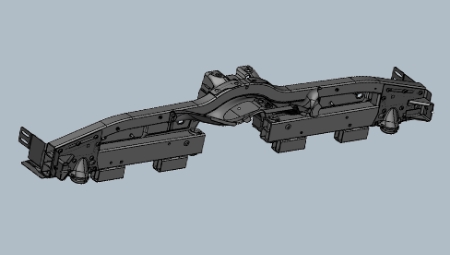

IHU components

- Sophisticated components using hydroforming (IHU).

- Development process including method development, FEM simulation, process development and tool design

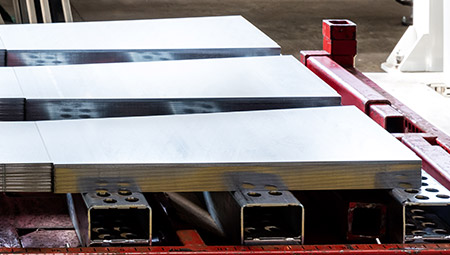

Tailor Welded Blanks

- Tailored blanks and patchwork blanks for locally precise adjustment of material requirements

Prototyping & small batch production

- Manufacture of production-ready series tools through to parts and components for series production

- Development and manufacture of tools, parts and components for concept and prototype construction

- Machining of a wide range of materials

Steel Service Center

- Processing specialist

- Large selection of stock shapes, fixed shapes, cut-to-size, slit strip and coils in all common grades and dimensions

Trade and processing

- Comprehensive range of high-quality steel products, rolled steel and tube products in all dimensions and grades: unmachined or industrially prefabricated

- Comprehensive, flexible, sustainable and customized solutions

Research and development

- Development and optimization of materials and manufacturing processes

- Innovative and customized solutions for customers worldwide

- Focus on sustainable and resource-efficient production

COMDaS

- Customer Online Material Data System

- Simply call up Salzgitter Flachstahl material data online

International Trading

- Your partner for worldwide trading in steel products, machinery, equipment, chemicals and pharmaceutical raw materials.

- Excellent market knowledge, an international distribution system and individual service are our strengths.